Share

Pin

Tweet

Send

Share

Send

I will show you how to make a simple drill from an ordinary nail, with which you can drill steel, wood, plastic, etc. Yes, you read it right, with this drill you can drill thick steel of the order of 5 mm. Savvy thing is a good thing, it will always help out in a difficult life situation. So, to increase the level of self-development, I suggest that you familiarize yourself with this method. Perhaps useful in life.

Making a drill for metal from a nail

We take a nail and grind off his point on an emery. You do not need to do this completely, about half.

With a hammer, we flatten the end under a flat screwdriver.

Next, on emery, we make cutting edges like a drill.

This is how it should turn out.

In principle, the drill is ready, but only wood, plastic or other soft metals can be drilled with it.

Drill hardening - carburizing

To turn a drill into a drill for metal, it must be hardened. To do this, we need a DC welding machine and a metal jar with crushed graphite. Graphite can be obtained from old brushes by grinding them with a file.

If there is no jar, you can use a piece of flat steel. We connect the positive electrode to the jar, and the negative to the nail.

Turn on the welding machine.

We lower the cutting edge and lower it in graphite. As soon as the masa begins to blush, we raise the nail. The main thing here is not to burn everything that has been machined. It is not necessary to overheat, we drive with a nail to achieve a small spark. The whole procedure lasts 1-2 minutes.

This method is called cementation. That is, the cutting edge is saturated with carbon, which in turn will add strength.

Then we clamp in a vice and saw off the hat.

The metal drill made of nail is done!

Metal test

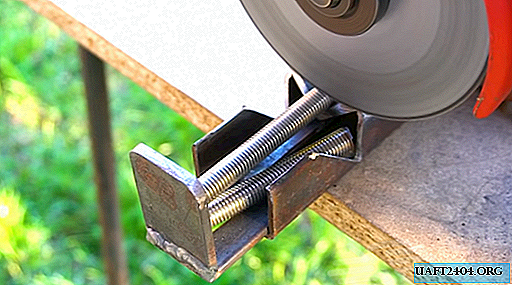

We pass to tests. We clamp the drill in the chuck of a vertical drilling machine.

And we drill a steel corner as an ordinary drill, periodically spraying with grease.

The hole is drilled.

We give the second attempt.

The outlet was drilled no worse than a conventional drill.

Now the task is more difficult - to check the stainless steel. It is known that it just cannot be done.

Also drill with grease.

Some more.

The hole is drilled.

Of course, the strength of such a drill for a long time is not enough. If you drill a tree, then in principle it will, but for steel the safety margin is limited to several holes, it all depends on the thickness of the steel.

In difficult situations, it may well help out. Bye everyone!

See the video for more detailed technology.

Share

Pin

Tweet

Send

Share

Send