From a small grinder you can make a compact wall-mounted belt sander, which is useful both in the garage and in a small home workshop.

The home-made belt grinding machine (or, as it is also called, a grinder) is designed for standard factory grinding belts with a width of 50 mm and a length of 610 mm. This is very convenient since you will not need to glue the tapes yourself.

First of all, it is necessary to cut a suitable length of a piece of metal strip with a width of 50 mm. In it, it will be necessary to drill a hole for the diameter of the shaft of the grinder. This can be done on a drilling machine or using an electric drill.

The main stages of work

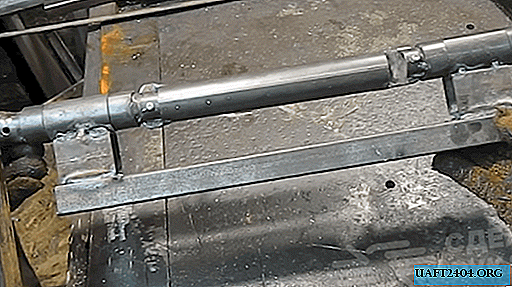

From a round metal pipe, it is necessary to cut a ring that fits in diameter to the "neck" of the angle grinder housing.

Two nuts need to be welded along the edges of this ring - a hexagon wrench bolt is screwed into them. Then the ring must be welded to a metal plate 50 mm wide.

At the next stage, you will need to make a drive roller from a piece of pipe and a clamping nut from a grinder. The roller is screwed onto the shaft of an angle grinder.

The author took the tension roller from the car. And the rubber pipe from the radiator is pulled onto this roller.

At the last stage, it remains only to strengthen the main plate, make some parts, after which you can proceed with the assembly of the structure.

For details on how to make a wall-mounted belt-grinding machine from a Bulgarian yourself, see the video on our website.