Sealing sanitary thread with linen is a classic way to seal threaded joints. Moreover, this is also the cheapest way, in comparison, for example, with a thread or a fum tape.

And the first thing to remember: when sealing a thread with flax, it is necessary to use a special sealing paste (UniPak or its analogues) paired with it. Otherwise, the flax will collapse and rot, and this will eventually lead to a violation of the sealing compound.

Now let's look at how to "pack" a threaded connection using flax. First, you need to separate a small bundle of flax from the braid (depending on the diameter of the thread itself). Most often, the amount of flax is determined by eye.

Step-by-step thread packing process

Before winding flax onto the thread of a pipe or fitting, it is necessary to prepare the thread itself. Using a pipe wrench, it will be necessary to make small notches (some fittings already have factory notches).

Notches are necessary so that the flax does not slip and does not peel off at the end of the thread. Also note that flax can only be used to seal metal pipes and fittings - it is not suitable for plastic fittings.

The edge of the flax is fixed approximately in the middle of the thread, then one turn back from the edge of the thread, after which the flax is wound clockwise.

It is necessary to lay flax in the "grooves" of the thread. When they reached the place where the “tail” was fixed, it must be tucked up, and then the flax is wound further - towards the end of the thread.

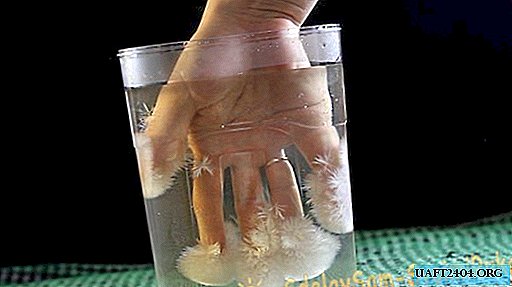

Then you need to make a couple more turns and return the edge of the flax to the beginning of the thread. After that, the flax is greased with sealing paste, and the fitting can be screwed on.

If you are interested in learning how to properly seal a threaded connection with a fum tape, then all information on this topic is in this article. For details on the use of flax, see this video.