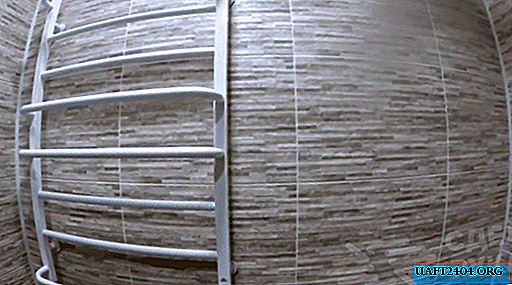

This version of a home-made open-type stove is ideal for a summer cottage - you can quickly warm it up or cook dinner on it, as well as boil a kettle. Dry branches and small logs are used as fuel.

The basis of the construction of the potbelly stove is a propane cylinder, so before you cut the case with a grinder, you must fill it with water to the top (preferably twice) to remove any condensate. If this is not done, then the gas cylinder may explode. Therefore, do not neglect precautions.

The main stages of work

First, markup is performed and a rectangular “window” is cut out in the middle. Edges are filed to remove burrs. If desired, you can make an oven with a door, additionally welded hinges. But in this case the potbelly stove will be open type.

You also need to cut off the handles and the upper part of the case - as a result, you should get a round hole, on top of which a "burner" is cut, cut from a thick sheet of metal. After that, you can begin to manufacture the built-in "exhaust" pipe.

From a steel pipe of suitable diameter, you need to cut off the long part and the "shorty", which are then welded to each other at an angle. In the upper side of the body of the container you need to cut a hole for the diameter of the "exhaust" pipe.

The support shoe is cut off, and instead of it three bolts are welded onto which removable legs of the potbelly stove will be wound. They are made of pipe, inside of which a nut of the right size is welded (under the thread of the bolt). Then a chimney is installed, after which the street stove is ready for use. The result was a fairly compact open-type oven, which, if necessary, can be transferred from one place to another without problems.