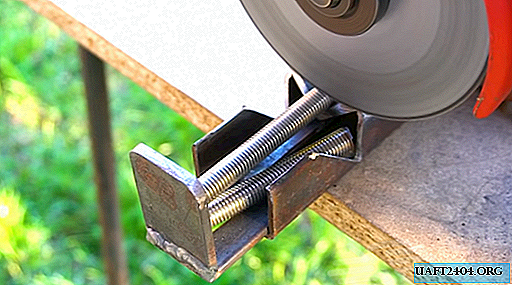

If you needed a compact vise to perform certain tasks, it’s not at all necessary to buy them in a store - they are easy to make yourself from improvised materials. For better and more reliable fixation of parts on the jaws of a vice, you can weld pieces of a flat file or a plate of hardened steel with notches.

For the manufacture of simple homemade vices, the following materials will be required: a steel square with sides 40 mm and a length of 12-15 cm, two pieces of a plate, a pin of suitable length, one bearing, as well as a hexagon, a strip and a nut. Many of the necessary materials can be found in every garage or home workshop, so the cost of doing it yourself is minimal.

Making a home-made vice: the progress of work

We apply a piece of strip to the steel square, markup, and then make a small depression - a "seat" for it. In the strip itself, you need to drill two holes for mounting to the table. Then in one of the plates we make a U-shaped cut in the thickness of the steel square. To the same plate in the center we weld the bearing.

We grind one end of the stud onto the cone, and weld the hexagon to the other. On one side of the square, it is necessary to weld a nut into which we screw the pin, and its truncated end we put into the bearing. The second plate is welded to the free edge of the steel square. All places of welding are well cleaned with a grinder.

To summarize

It's just that simple homemade compact vice can be made from improvised materials that will be useful in a garage and home workshop. See the step-by-step manufacturing process in the video on our website.