Share

Pin

Tweet

Send

Share

Send

Its author was able to assemble it literally from the old washer, slightly modernizing and correctly using the resources of the nearest river in its suburban area. He claims that he has been living for several years without being connected to electric networks, and does not pay a dime for electricity. There is enough power from the hydrogenerator to supply not only all electrical appliances in the house with electricity, but also to pull the work of the workshop with power tools. How is this possible? Let's take a look together.

The principle of operation of a hydroelectric generator

This home development uses the native housing of the washing machine. The engine is remounted into generator mode, and placed back to its seat. The Pelton wheel is used as a driving turbine that accumulates water flows and transfers kinetic energy to the generator. An alternating 3-phase current received at the generator output is passed through a rectifier of three diode bridges. Direct current is supplied to charge the batteries through the controller, and from them to the inverter 12V / 220V, again receiving a variable frequency.

Materials, tools

Materials:

- Old inverter washing machine;

- Pelton Wheel;

- A small stretch of awning;

- Plywood;

- Plexiglass or plexiglass;

- Silicone;

- Waterproofing for plastic - paint or mastic;

- Self-tapping screws, nuts, washers, bolts and sandpaper.

Tool:

- Drill with a core mill, drills and a nozzle for self-tapping screws;

- Reciprocating saw or jigsaw;

- Hand tools: wrenches, pliers, a paint knife and a gun for silicone.

We assemble a hydroelectric generator

Preparatory dismantling

First you need to disassemble the washing machine, leaving only the parts we need.

The machine is a vertical type, so we remove the end cover from the front side and dismantle the electronic control panel for washing modes.

We take out the outer drum and dismantle the pump and excess water supply hoses.

We do not need a flywheel for washing, as in other things, and the inner steel container for linen.

All that remains is an external plastic drum and an engine on the shaft.

As we can see, a remounted inverter motor already generates electricity when the shaft rotates.

Now it is necessary to disassemble the engine, leaving only the shaft with bearings on the housing.

Production of a hydraulic turbine

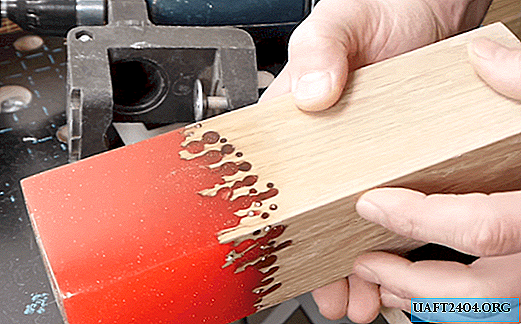

A rubber gasket cut from an old camera will help seal our shaft. We make a hole in it in the middle, and push it tightly onto the shaft shaft.

A small Pelton wheel will draw water. This invention is almost one and a half hundred years old, but it still does not lose its relevance and is applied even at some hydroelectric power stations. It must be fixed to the shaft so that it can move freely and does not touch the housing.

We mark a hole in it for water supply under it, and drill it with a crown milling cutter.

Using a jigsaw or reciprocating saw, we make a drain hole in the shape of a rectangle, and close it with screws with a piece of waterproof tent. It should turn out like this (photo).

Next, you need to make a cap for the tank of our hydraulic turbine. We make it from a piece of moisture-proof plywood, cutting a circle equal to the inner diameter of the drum with a jigsaw. In the plug itself, we make an inspection hole to control the operation of the unit. Which will then be closed by plexiglass.

Coat the end of the plywood with silicone, and push it inside. We fix it with screws through the turbine housing.

We cut out the gasket for plexiglass from the rubberized material, and glue it on the silicone to the plywood.

We drill four holes on the sides of the rectangle of the window, and on the inside put clamping bolts in them. We will fix plexiglass on them so that it is removable in case of unforeseen breakdowns.

We seal the joint of our plug with the body in silicone.

To protect the electrical part of the unit, the author installed an additional plastic casing on the edge of the turbine using self-tapping screws. The plastic case itself was painted with paint to protect the plastic from cracking.

It was the turn to assemble the engine, install it on the unit. We fix the stator on the mounting bolts.

To obtain a direct current for charging batteries, we fix the bar of three diode bridges, each for a phase.

We cover the engine with the rotor cap, and plug the excess drain holes for the hoses remaining in the housing.

Installation and Connection

Our hydrogenerator is almost ready. It remains to fix it on the frame frame from the welded corners, and adjust the water supply with the help of hydrants. The output power of the generator can be controlled by the force of the pressure, or by the diameter of the orifice of the nozzle of the tap supplying water directly to the turbine itself. Directional discharge will also ensure the return of water without harm to the river.

The turbine housing can be secured to the lashing strap to secure the loads on vehicles.

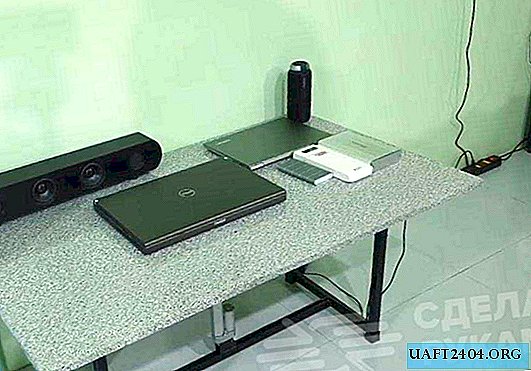

We check the operation of the generator, and measure the current and output voltage with a tester. The author assures that when the water pressure in its area, the unit gave out 21A at 29V, which equals 600W. With an increase in the nozzle of the crane, the power reached 900W.

The electrical circuit proposed by the author of this homemade product is not limited to one generator only. For the planned consumption of electricity in the network, a stable voltage and current are required, which are capable of issuing storage capacities - batteries. Inverting a small voltage to sufficient for household, you can organize the supply and distribution of it along the house wiring to electrical appliances. The author also advises using an electronic controller that shows the degree of battery charge, current consumed and output, temperature, etc.

Natural resources, which are abundant around us, can really be used for good. All that is needed is a little knowledge of electrical engineering and old spare parts lying around in the backyard. And the rest will help the ingenuity and resourcefulness of a true lover of inventions, because it is precisely such people who are behind the movement and development of technological progress.

Share

Pin

Tweet

Send

Share

Send