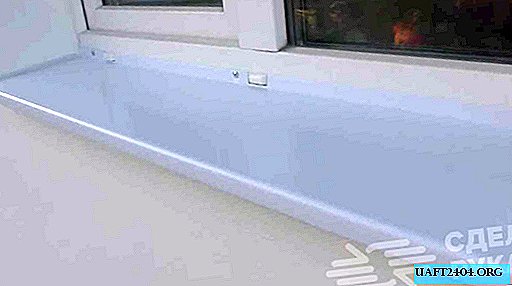

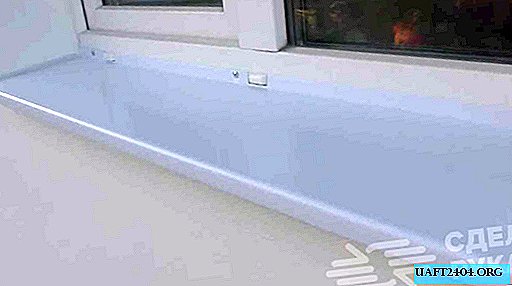

In this review, the author shows a step-by-step process of installing plastic (PVC) castings on windows. Why exactly plastic, but not metallic ebbs? Everything is simple here - PVC ebbs are less noisy in the rain.

First of all, measure the width of the window opening and cut off the PVC tide of the desired length.

You can cut the tide using a hand saw. You will also need to cut off the end caps in size.

Next, try on the windowsill and mark out the places where it will be necessary to make cuts for drainage holes. With the help of a clerical knife we remove the burrs.

The main stages of work

After repeated fitting of the ebb, it is necessary to process its back side with sandpaper so that it becomes rough. This is necessary for better adhesion to a concrete or plastered base.

To fix the window sill, the author uses special mounting glue. It is better to buy transparent glue so that the seam is invisible.

At the next stage, we apply mounting glue to the return surface of the PVC cast. The author applies the adhesive pointwise. Also do not forget to smear the back side of the windowsill.

After that, we proceed to the ebb installation. We fasten it to the frame of the plastic window with screws with a press washer (along the edges and in the middle).

On top, we additionally press the window sill with five- or six-liter eggplants with water.

To fill the gaps between the slope and the side of the PVC ebb tide, the author uses sanitary silicone. The main thing is that the sealant is resistant to moisture and UV radiation.

For details on how to install PVC ebbs on the windows with your own hands, we recommend that you look in the video on our website.