For grinding (grouting) walls after puttying, manual grinding blocks with abrasive mesh are used. And in the process, a lot of dust is formed. To reduce its quantity, it is possible to make a simple dust extraction from plastic fittings.

For the manufacture of this homemade product, you will need a piece of plastic pipe of the desired diameter, a plastic corner with a fixing nut and a small portion of a 50 ml syringe.

First, it will be necessary to cut a piece of plastic pipe with an external thread, onto which a corner will then be wound. And for this you can use a hacksaw for metal.

The main stages of work

At the next stage, the master cuts off the upper part of the syringe, which will need to be put on a piece of plastic pipe. The end of the pipe segment and the parts that will be inside the grinding unit must be carefully trimmed with scissors.

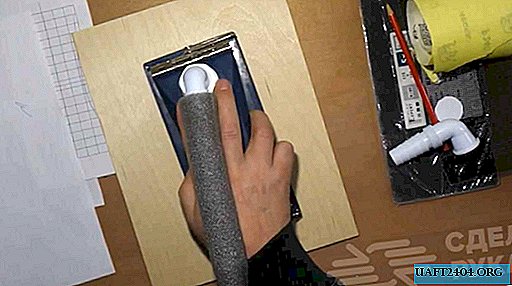

Next, it will be necessary to drill a hole for a plastic pipe in the upper part of the grinding block using a drill with a diameter of 30 mm.

Then the nozzle is installed, it is fixed from the inside by a part from the syringe. A plastic corner is screwed onto this pipe, which is connected to the vacuum cleaner tube.

In the end, it remains only to drill holes in the sole of the grinding bar, through which dust will be removed during grinding. The master uses a paper template to drill holes.

Details on how to make a dust extraction for a manual grinding unit can be found in the video on the website.