A simple refinement of the usual F-shaped clamp will allow you to "fit" it for use in conjunction with a home-made cutting machine from the grinder. Also, such a converted clamp can be used on a welding table or joiner's workbench to fix various metal and wood workpieces.

In particular, the modified F-shaped clamp is useful in cases where you need to cut a short segment of any part (corner, metal strip, profile pipe, etc.) so that you do not once again expose your fingers under the cutting disc of the grinder.

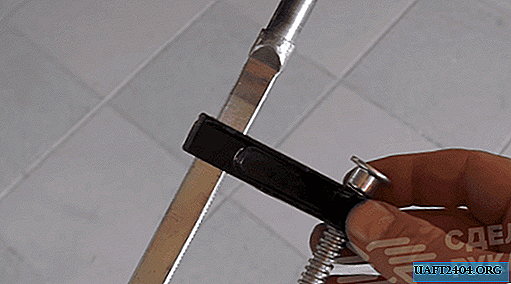

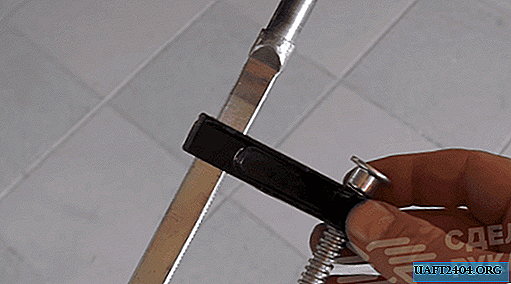

The finalization of the F-shaped clamp is quite simple and does not take much time. You just need to trim the upper part under the root. Then weld instead of the cut-off part a steel “finger” (can be made on a lathe) or a regular bolt of suitable diameter. In general, nothing complicated - everyone will cope with this task.

The main stages of work

First of all, we cut off the upper sponge of the F-shaped clamp with a grinder. If the workshop has a lathe, then it is possible to carve a steel “finger” on it, which will be used as a supporting element for rigidly fixing the clamp on the work table of the cutting machine.

If there is no turner, then you can not bother and take a regular bolt. We weld a “finger” or a bolt to the cut off part of the clamp, and then drill through holes in the work table of the cutting machine (joiner's workbench or welding table) next to the stops.

Then everything is simple - we install the “finger” of the F-shaped clamp in the drilled hole, and fix the workpiece or part with the lower clamping sponge. For a detailed process of finalizing the F-shaped clamp for a home-made cutting machine, see the video on the website.