With this homemade product, which can be made from a conventional glass cutter, you can drill a hole in various glass products (bottles, cans, sheet glass, etc.). The nozzle itself is installed in the electric drill. It is not advisable to use a screwdriver, since its power is less.

To make such a homemade nozzle you will need one cutting element of a glass cutter, as well as a stud and a piece of rigid steel wire. Of the main tool, you only need a drill and a drill (you can use the usual manual hacksaw for metal). The drill itself for drilling holes in the glass can be done in literally 30-40 minutes.

The process of making drill for electric drill

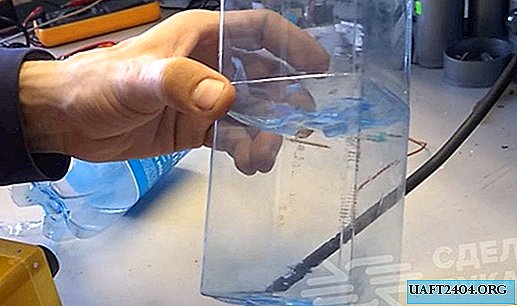

To begin with, we disassemble the glass cutter and remove one cutting element. Next, we take an ordinary hairpin with a diameter of 3 mm. In its upper part (where the thread is not threaded), it is necessary to drill a hole with a diameter of 1.5 mm. Next, using a drill or manually using a hacksaw, we make a shallow axial cut.

Insert the cutting element from the glass cutter into the resulting slot in the hairpin. You can fix it in the "landing nest" using ordinary wire with a diameter of 2 mm. We bite off the excess parts of the wire with side cutters and rivet the edges. An ordinary bolt with a nut cannot be used, as they will protrude.

The main stages of work on the manufacture of a homemade drill nozzle for a drill, with which you can drill holes in the glass, see the video on our website. Leave your comments what you think about this device.