The possibilities of 3D pens are impressive: with the help of a compact electronic device you can draw "live" figures, create complex structures from plastic and even repair toys and various plastic accessories. This is a great gift for children, as well as an indispensable tool for creative personalities - artists and interior designers. To learn how to use the device for three-dimensional printing, it is enough to spend quite a bit of time, because everything is clear on an intuitive level.

Features of use

3D pens are a "magic wand" that can literally draw in the air. Although it is better to do it all the same on a laminated surface - it will be much more practical and convenient. For all fans of DIY 3D pen is a real find. Using special plastic as the initial “raw material”, you can work wonders: create unique pictures that immediately become tangible, draw patterns and stencils downloaded from the Internet, and make various decorative elements.

If the first 3D pens were deprived of many functionalities, then modern samples allow you to experiment and not limit the flight of creative imagination. In your hands a powerful tool for 3D modeling, which is thought out to the smallest detail. With the help of a small three-dimensional printer it is possible not only to create original art masterpieces, but also to effectively solve some issues of a household nature. You just insert the plastic into a special hole, it heats up to the required temperature, and when it comes in contact with air, it freezes almost instantly. Everything is simple, like twice two, but it’s very interesting.

Types of pens for 3D printing

Today on sale you can find 2 types of devices for drawing with molten plastic, which are similar in appearance, but differ in some features. 3D pens are:

- cold - draw with special photopolymers, quickly freeze under the influence of ultraviolet radiation;

- hot - work only with polymer alloys, they can melt at different temperatures.

If cold 3D-printers can be safely given into the hands of a child, then with hot devices, care must be taken even by an adult to not get burned. Some models are additionally equipped with a built-in fan, which blows plastic at the exit of the nozzle, as a result of which the resulting figures harden faster. The melting temperature may vary, depending on the specific configuration of the electronic device, but usually this indicator is in the range from 100 to 240 degrees.

The cost of a 3D printer depends on technical specifications and functionality. Inexpensive products have a standard set of options and are more suitable for beginners who want to try strength in the field of three-dimensional modeling. For more advanced users, practical devices of a new generation with an LCD display have been specially developed, which displays the basic information during the drawing process.

The principle of operation of the device

A 3D printer is very similar to a regular pen, but instead of traditional ink pens, a special plastic thread with a thickness of about 3 mm is used. In the upper part of the housing there is a hole for a plastic thread or bar. After installing the 3D “ink” inside, you need to press the button, after which the built-in mechanism with gears will automatically tighten the plastic directly to the extruder, where the “raw material” is heated to a predetermined temperature, melted, and then squeezed out through the print head in a “liquid” form.

Before operation, the device must be preheated - it usually takes from a few seconds to a couple of minutes, depending on the model. Readiness for drawing is determined by the light indicator. When the green light turns on, you can begin to work. There are 2 indicators on the case: one is responsible for the readiness for work, the other is a signal that it is connected to the mains. In addition to buttons for feeding and pulling plastic, there is an additional slider with which you can adjust the feed rate of the material.

To turn on the device, you need to press the "forward" button. Three-dimensional printers for home use can operate from an adapter that plugs into an electrical outlet, or directly from the built-in battery. In the latter case, the cost of the device will be slightly higher than the "stationary" models. Of the main advantages of 3D mechanisms can be identified:

- compact size and light weight;

- practicality and usability;

- the possibility of a combination of colors and materials;

- ergonomic stylish design;

- easy care after use.

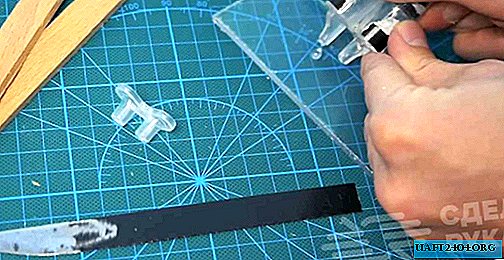

The standard equipment of the device includes a 3D pen, a power supply (adapter), instructions for use and a set of plastic "probes" of three colors. In some models, the kit also provides a small plastic screwdriver - it is used to adjust the heating temperature of the source material. There is a rubber plug on the case, under which a special screw is located. By turning it left or right, you can decrease or increase the temperature at your own discretion.

Types of plastic for work

For three-dimensional drawing, special plastic is used (most often ABS), which can be in the form of short rods or skeins. In the first case, the drawing time is usually limited to 1-2 minutes, since the device quickly eats up a bar of plastic. The disadvantage is that you constantly need to charge the device with new batches of material. In the case of skeins, the situation is different - you can create calmly, without being distracted by trifles.

There are devices for PLA plastic. Environmentally friendly material significantly expands the boundaries of creative imagination. It is convenient to work with it on any surfaces, including various fabric bases. PLA DIY 3D printing pen is an ideal tool for professional designers and artists. Most often, such a three-dimensional printer is used in practice to create three-dimensional patterns and designs. But for maximum efficiency, it is better to immediately purchase a universal device that is equally well suited for using PLA and ABS plastic.

It is worth noting that there are some differences between the plastics for 3D pens. Figures made of ABS material may shrink over time, and a characteristic smell of burnt plastic forms during the drawing process. With this material it is possible to glue the broken elements of children's toys and repair other products made of ABS plastic. The PLA material is made from corn, so during the melting process you can catch the light aroma of fried popcorn. The melting point of ABS plastic is slightly higher compared to PLA material.

On the shelves of online stores there are 3D pens of different models and configurations, but in the vast majority of cases they are all made in China. Before buying a device, carefully read the instructions, as well as technical specifications. It will not be superfluous to read customer reviews on the forum - this way you will protect yourself from buying low-quality products. Draw for your pleasure and be sure to share your own impressions in the comments. For more information about the possibilities of 3D pens, see the special video on our website.

Comparison table of budget models of famous manufacturers

| 3D pen brand | Type of plastic | Weight gram | Price, ₽ |

| FuntastiqueRP600A * | ABS and PLA | 40 | 3500 |

| MyriwellRP100A * | ABS | 64 | 2900 |

| SPIDER PENSTART * | ABS | 65 | 3400 |

* No LCD display