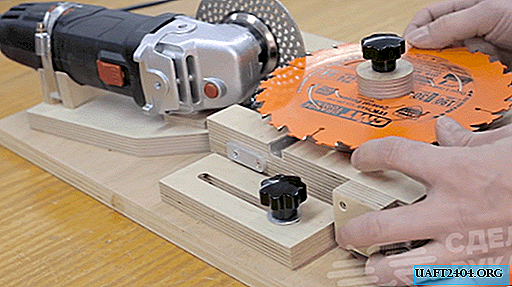

This home-made device can conditionally be called a clamp for welding, but in design it is slightly different from ordinary clamps.

The name "third hand" is more suitable. Its main task is to rigidly fix steel billets (profile, plates, corners, etc.) on the center of the table with a wooden surface (or if the tabletop is made of chipboard and plywood).

Design features

At the same time, such a clamp acts as a "mass" for welding. In general, this device simplifies the process of welding at home, when it is necessary to weld the workpiece perfectly evenly at an angle of 90 or 45 degrees.

At the same time, the shoulder of the clamp is adjustable in length and freely rotates in different directions, which allows you to fix the workpiece anywhere on the table. For the manufacture of a "third hand", profile pipes, pieces of corner and metal scraps are used, and the clamp is attached to the wall, so it does not take up much space in the workshop or garage.

Clamp making process

First you need to make a shoulder clamps from profile pipes of different sizes. In this case, it is desirable to roll a profile with sides of 15x15 mm on one side for greater rigidity, and also to better fit into a profile pipe of 20x20 mm.

Then a bracket is made, which will be attached to the wall for articulation. In the upper pipe, select the groove for the fixing bolt. In the 15x15 mm profile, a hole with a diameter of 8 mm is drilled at the end, after which the M8 nut is welded.

Further, from the twentieth and fifteenth profile pipe is made the clamping part of the "third hand", as well as a makeshift loop from a round timber and two pieces of a round pipe. Then all the elements are interconnected. The detailed process of manufacturing and assembling a clamp for welding, you can see in the video on the site.